Ultra Filtration

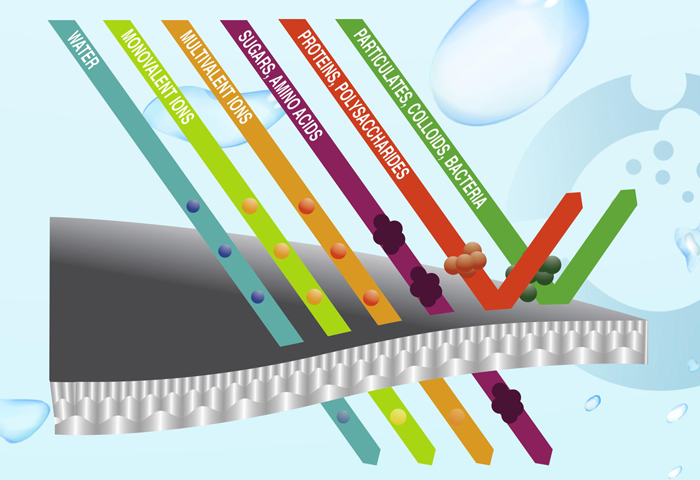

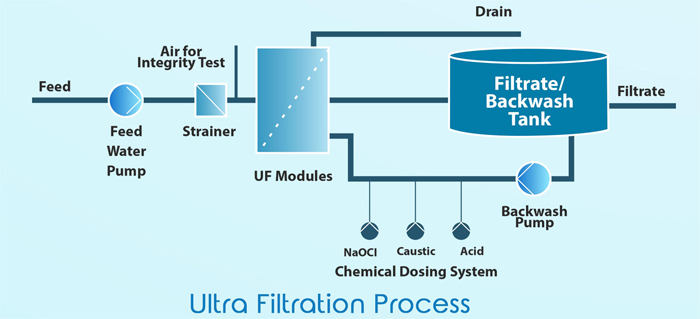

- Ultra Filtration technology uses a membranes wall to remove particles as small as 0.01 microns, including bacteria, viruses and colloids, impurities meeting increasingly harsh water quality standards around the world providing purified water.

- Ultra Filtration (UF) is a pressure-driven purification technology in which water and low molecular weight material pass through a membranes while particles, colloids and macro molecules are rejected, yet does not remove ions and small molecules. Flow through the semi-permeable membranes is achieved by applying a pressure gradient between the outer and inner walls of the membranes structure.

- UF membranes typically have pore sizes in the range of 0.01-0.05 µm which contributes to a high removal capability of bacteria, viruses, colloids and impurity thereby producing highly purified water. UF membranes basically have a service life of three to seven years or longer, compared to reverse osmosis membranes. They are commercially available in hollow fiber, tubular, plate and frame, and spiral wound configurations.

Applications of Ultra Filtration

- Filtration of sewage from paper pulp mill

- Cheese manufacture, see ultra filtered milk

- Removal of pathogens from milk

- Process and waste water treatment

- Fruit juice concentration and clarification

- Dialysis and other blood treatments

- Desalting and solvent-exchange of proteins